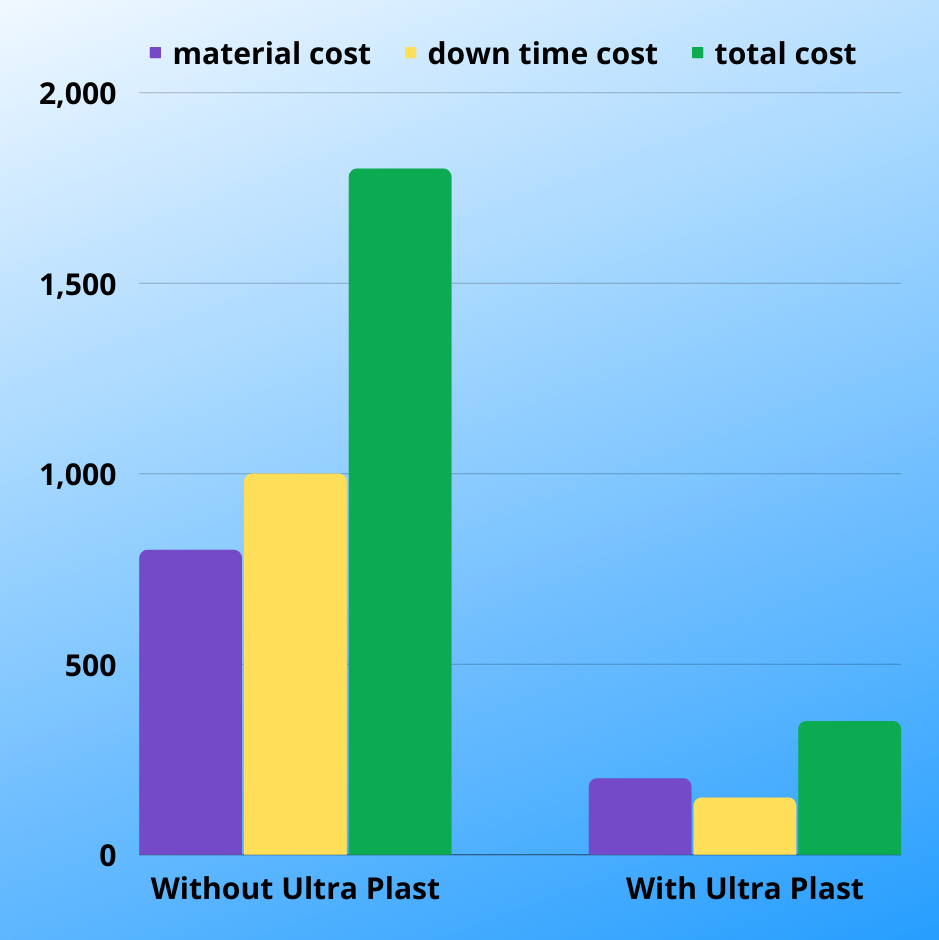

COST SAVINGS

WHEN COMPARE ULTRA PLAST WITH OTHER PURGE COMPOUNDS

OR REGULAR PLASTIC RESIN

IN THE PURGE PROCESS.

OF COURSE, IF ONLY LOOK ON THE MATERIAL PRICE THE COST MAY NOT BE INTERESTING FOR THE BUYER,

BUT IF CONSIDER FOR TOTAL COST THAT COME FROM REDUCE COST OF MATERIAL WASTE, REDUCE TIME

AND ENERGY, REDUCE DEFECT PARTS AND ALSO THE TIME SAVING

CAN CHANGE TO CREATE THE NEW GOOD QUALITY PRODUCTS.

ALL OF THE SAVING COST WILL GIVE THE FAST PAYBACK RETURN TO ULTRA PLAST CUSTOMERS.

ADVANTAGES

SAFE AND EASY HANDLING

EXCELLENT EFFICIENCY

NO WAITING TIME, SO SAVES FOR YOUR CLEANING OPERATION

NO SMELL: NO UNHEALTHY GAS

I FUSED FREQUENTLY, IT PROTECTS STEEL FROM OXIDATION,

MAKING CLEANING OPERATIONS EASIER AND FASTER

CAN CLEAN ALL TYPES OF MACHINE

EVERY GRADE OF ULTRA PLAST PRODUCTS WAS NON TOXIC,

NON ABRASIVE, NO SOLVENT,

NO ACID, OR ALKALI.

ULTRA PLAST MAKE IT POSSIBLE TO CHANGE COLOURS THOROUGHLY IN HOT RUNNER SYSTEMS, DIE,

MELT PUMP, WHICH MOST OF CONVENTIONAL PURGING COMPOUNDS CANNOT.

THE READY-TO-USE PURGE COMPOUND

NO NEED PRIOR BLENDING

OR ANY OTHER PREPARATIONS.

JUST STOP THE OLD PRODUCTION, PUT THE ULTRA PLAST IN A MACHINE

AS RECOMMENDED QUANTITY,

PURGE

AND AFTER PURGING CAN IMMEDIATELY RUN THE NEXT PRODUCTION.

EXCELLENT EFFICIENCY

THE COMPOUND WORKS WITH A CHEMICAL REACTION.

DUE TO PARTICULAR CHEMICAL COMPONENTS, COLOURED AND

BURNT POLYMERS, INCRUSTATIONS,

BLACK SPECKS AND ALSO RUST

ARE SOFTENED, REMOVED

AND EJECTED FROM THE PRESS.

CONSEQUENTLY NO CHEMICAL ACTION IS MADE ON THE MACHINE PARTS.

USEABLE FORALL TYPES OF THERMOPLASTICS

ULTRA PLAST CAN BE APPLIED FOR ALL TYPES OF THERMOPLASTIC SUCH AS ENGINEERING PLASTICS, SOME SUPER-EBGINEERING PLASTICS, MEDICAL PLASTICS, ETC.

WITH VARIOUS OF ULTRA PLAST GRADES SO WE DEFINITELY HAVE A SUITABLE PURGE COMPOUND FOR YOU.